TROMADUR®

- Cost-effective material based on hard ferrites

- Manufacturing process: Injection moulding

- Choice of isotropic or anisotropic materials available

- The materials used are barium and strontium ferrites (hard ferrites) in various plastic binders

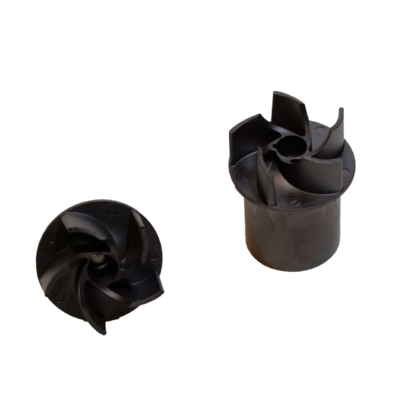

Magnets for rotor and sensor applications:

Plastic-bonded permanent magnets are used in many areas of industry due to their properties.

These include:

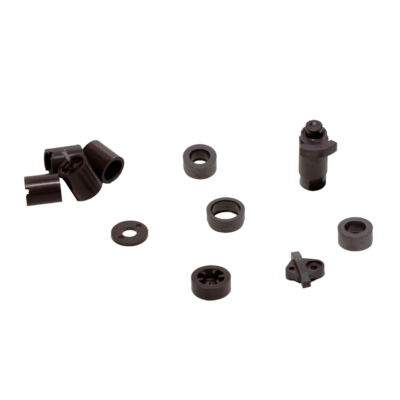

- considerable freedom in forming

- low dimensional tolerances

- tight magnetic tolerances

- good magnetic homogeneity

- good long-term stability

- low edge breakage sensitivity

- corrosion resistance

- flame protection optional

- temperature stability up to approx. 125°C

Further benefits of TROMADUR® are:

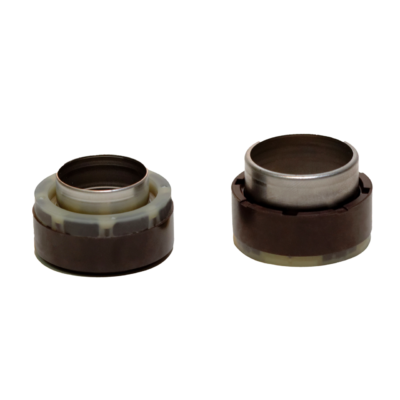

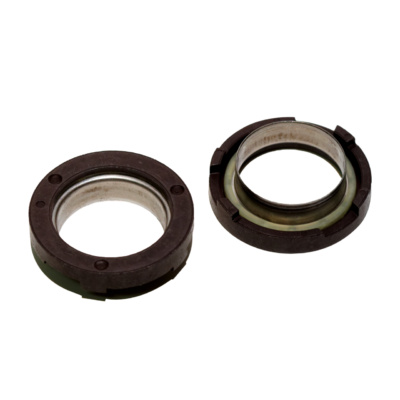

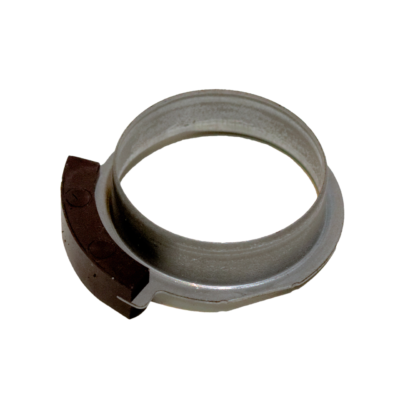

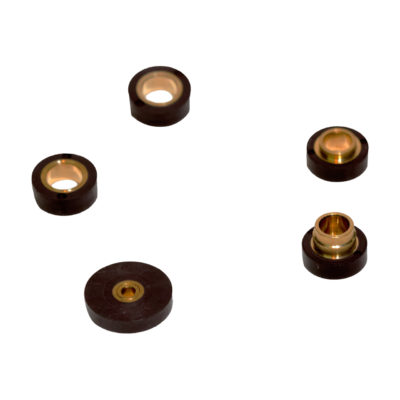

- Inserts such as axles or bushings can be included in the production process in a single operation.

- Centring collars, anti-rotation devices, holding stays, bases, pinions or similar can be taken into account directly when designing the magnet. This results in simplified assembly and cost savings for the subsequent installation.

- low specific gravity

- good elasticity properties

- magnetic pole patterns from the sine to the approximated rectangular signal are possible

- Uniformity of the magnetic signal such as:

- low pole difference

- exact pole pitch

- extreme flank rise

- good stability against external magnetic fields

- minimum pole spacing with lateral preferred direction

- connections with press-in parts without use of adhesives

- high displacement forces

- marking with parts No. or similar directly during the injection

- no mechanical reworking